Advanced Materials Research Lab

Ballistic, Blast, and Fragment Impact of Composite Metal Foam Armors

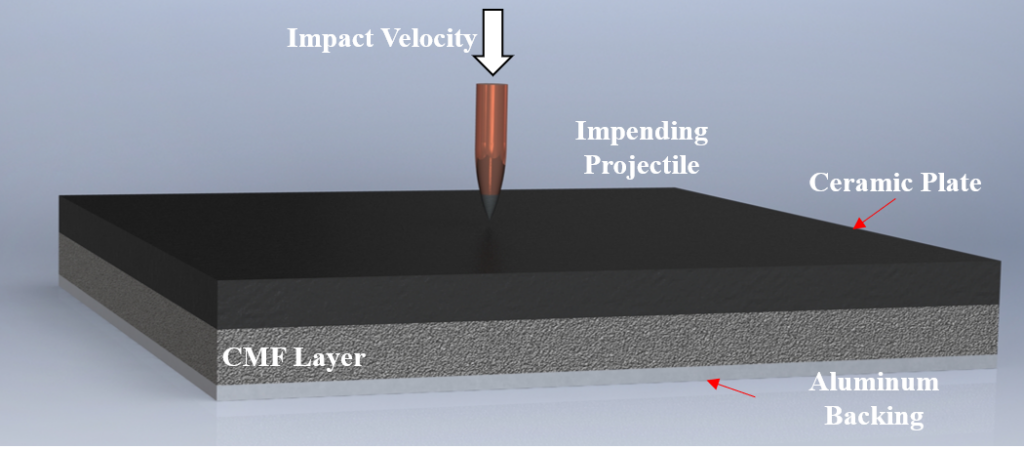

Diagram of the impact and CMF armor arrangement. Figure first published in J. of Composite Structures: 10.1016/j.compstruct.2019.111032.

Diagram of the impact and CMF armor arrangement. Figure first published in J. of Composite Structures: 10.1016/j.compstruct.2019.111032.

Jacob’s primary research has focused on manufacturing and testing composite metal foam armors in an effort to reduce the weight of current armor systems while improving ballistic protection. These novel armors absorb the impact energy of the bullet through compression. Composite metal foam is able to compress to strains greater than 60% and absorb the kinetic energy of the bullet and fragments in doing so. Jacob’s work has been published in various journals and reached the top most downloaded articles for Advanced Engineering Materials and Composite Structures. Click here to learn more.

Composite Metal Foam Sandwich Panels

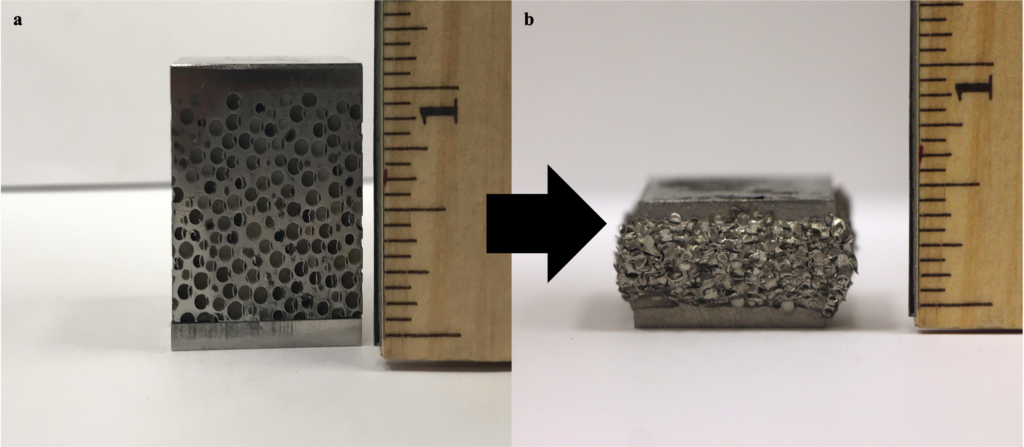

Image of composite metal foam core sandwich panel (a) as manufactured and (b) strained to 60% under compression. Image credit: First published in Proceedings of the 11th International Conference on Porous Metals and Metallic Foams, “Study on the Mechanical Properties of Composite Metal Foam Core Sandwich Panels.”

Image of composite metal foam core sandwich panel (a) as manufactured and (b) strained to 60% under compression. Image credit: First published in Proceedings of the 11th International Conference on Porous Metals and Metallic Foams, “Study on the Mechanical Properties of Composite Metal Foam Core Sandwich Panels.”

This project was funded through the Department of Transportation in order to explore CMF as a possible energy absorption material for tank cars during accident conditions. The first part of the project, was to manufacture and characterize CMF sandwich panels. The sandwich panels where imaged using Optical Microscope, SEM, and EDS following surface preparation. Samples were then cut and tested under compression, tension, and bending following ASTM standards. Click here for more information.